Understanding Injector Correction Techniques

This guide delves into the intricate process of "Коррекция Форсунок," a critical aspect of modern automotive maintenance. Injector correction, an essential service for maintaining optimal engine performance, involves precise adjustments to ensure fuel injectors function efficiently. This process is vital for enhancing fuel economy, reducing emissions, and prolonging the life of an engine.

The Importance of Injector Correction

As automotive technology evolves, the precision and efficiency of vehicle components become increasingly crucial. One such component is the fuel injector. "Коррекция Форсунок," or injector correction, is a process aimed at ensuring that fuel injectors deliver the correct amount of fuel at the right time. This is essential for maintaining engine performance, improving fuel efficiency, and reducing harmful emissions. Without proper injector correction, vehicles can suffer from a myriad of performance issues that not only affect drivability but also lead to increased operational costs.

Understanding Injector Functionality

Fuel injectors play a pivotal role in the internal combustion process, as they are responsible for spraying fuel into the engine's combustion chambers. The precise timing and amount of fuel delivered are critical for optimal combustion and overall engine efficiency. Any deviation in the injector's performance can lead to issues such as increased fuel consumption, reduced power, and higher emissions. Understanding how injectors work involves delving into several key concepts, including the injector's design, the role of fuel pressure, and the impact of engine management systems on injector performance.

Fuel injectors are typically electronic devices controlled by the engine's electronic control unit (ECU). The ECU determines when and how long to open the injector based on various inputs, including throttle position, engine temperature, and air-fuel mixture. This level of precision allows for better performance compared to older carburetor systems. However, this complexity means that any malfunction in the injectors can have a significant impact on engine performance, highlighting the importance of regular maintenance and correction.

Why Injector Correction is Necessary

Over time, fuel injectors can become clogged or experience wear and tear, affecting their performance. Injector correction involves cleaning and recalibrating these components to ensure they function as intended. This process can be complex, requiring specialized equipment and expertise to adjust injector settings accurately. Regular injector correction can prevent long-term engine damage and help maintain optimal vehicle performance.

Factors contributing to injector issues include the quality of fuel used, the presence of contaminants, and the design of the injector itself. For instance, low-quality fuel that contains sediment or impurities can lead to clogging, while injectors made from inferior materials may wear out more quickly. Additionally, the driving habits of the vehicle owner can also influence injector performance. Frequent short trips can prevent the injectors from reaching optimal operating temperature, leading to moisture buildup and corrosion.

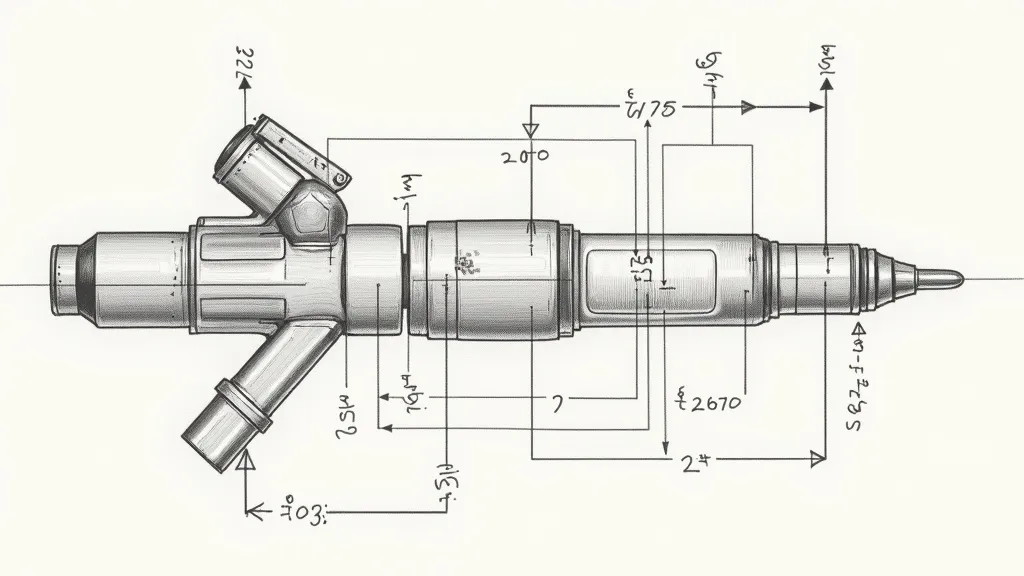

Steps Involved in Injector Correction

Injector correction typically involves several steps:

- Diagnosis: Using advanced diagnostic tools, technicians assess the performance of fuel injectors to identify any discrepancies in fuel delivery. This may involve checking the injector pulse width, flow rate, and resistance.

- Cleaning: Injectors are cleaned using specialized solutions to remove carbon deposits and other contaminants that can impede performance. This step is crucial as even minor blockages can lead to significant performance drops.

- Calibration: Technicians adjust the injector settings to ensure precise fuel delivery, often using computer-aided equipment for accuracy. This calibration ensures that the injectors are delivering the right amount of fuel for the current engine conditions.

- Testing: After calibration, injectors are tested to verify their performance and ensure that they meet manufacturer specifications. Testing can include flow tests and spray pattern evaluations to ensure optimal functionality.

Benefits of Regular Injector Correction

Regular injector correction offers numerous benefits, including:

- Improved fuel efficiency: Well-maintained injectors ensure that fuel is delivered efficiently, translating to better gas mileage and lower fuel costs.

- Enhanced engine performance: Correctly functioning injectors contribute to smoother acceleration, improved throttle response, and overall better vehicle performance.

- Reduced emissions: By ensuring a complete combustion process, injector correction can significantly decrease harmful emissions, making your vehicle more environmentally friendly.

- Extended lifespan of the engine and injectors: Regular maintenance helps prevent premature wear and tear on engine components, including the injectors themselves, leading to a longer vehicle lifespan.

Common Injector Issues

Understanding common injector issues can help vehicle owners recognize symptoms early, allowing for prompt maintenance. Here are some prevalent problems associated with fuel injectors:

- Clogging: Over time, fuel injectors can become clogged due to deposits from fuel, dirt, and other contaminants. This leads to uneven fuel distribution and poor engine performance.

- Leaking injectors: Fuel injectors can develop leaks due to wear or damage, causing excess fuel to enter the combustion chamber, which can lead to flooding and other performance issues.

- Electrical issues: Injector performance can also be affected by electrical problems, such as faulty wiring or a malfunctioning ECU. This may result in injectors not opening or closing correctly.

- Wear and tear: Over time, injectors can wear out, leading to a decrease in precision and function. This wear can be exacerbated by using low-quality fuel.

FAQs

What are the signs that my vehicle needs injector correction?

Common signs include poor fuel economy, rough idling, and engine misfires. Additionally, you may notice a decrease in acceleration, unusual noises from the engine, or a check engine light illuminating. If you experience these issues, it's advisable to have your injectors checked as soon as possible to prevent further damage.

How often should injector correction be performed?

It varies depending on the vehicle and usage, but generally, every 30,000 to 50,000 miles is recommended. However, for vehicles that are frequently driven in harsh conditions or use lower-quality fuel, more frequent checks may be necessary. Always consult your vehicle's owner manual for specific recommendations.

Can I perform injector correction myself?

While basic cleaning can be done at home using fuel injector cleaning additives, calibration and testing require specialized equipment and should be conducted by professionals. Attempting to calibrate injectors without the proper tools can lead to further complications and potentially damage the engine.

The Future of Fuel Injection Technology

As the automotive industry progresses, fuel injection technology continues to evolve. Innovations such as direct fuel injection, which injects fuel directly into the combustion chamber rather than the intake manifold, have emerged to enhance performance and efficiency. This technology offers more precise fuel delivery, reducing emissions and improving fuel economy.

Additionally, advancements in engine management systems allow for more dynamic control over fuel injection, adapting to various driving conditions in real time. These systems can adjust the injector timing and duration based on factors such as engine load, temperature, and driver demand. This level of sophistication requires even more stringent maintenance practices, emphasizing the importance of regular injector correction.

Environmental Impact of Injector Performance

The performance of fuel injectors plays a significant role in the environmental impact of vehicles. Inefficient fuel delivery can lead to incomplete combustion, resulting in higher levels of carbon monoxide, hydrocarbons, and nitrogen oxides being emitted into the atmosphere. Regular injector correction not only helps improve a vehicle's performance but also contributes to environmental protection by reducing harmful emissions.

Moreover, as governments worldwide impose stricter emissions regulations, vehicle owners must prioritize maintenance practices that ensure compliance. Ignoring injector maintenance can lead to vehicles failing emissions tests, resulting in costly repairs and fines. By maintaining optimal injector performance, vehicle owners can support environmental initiatives while also benefiting from improved fuel economy and vehicle performance.

Advanced Technologies in Injector Correction

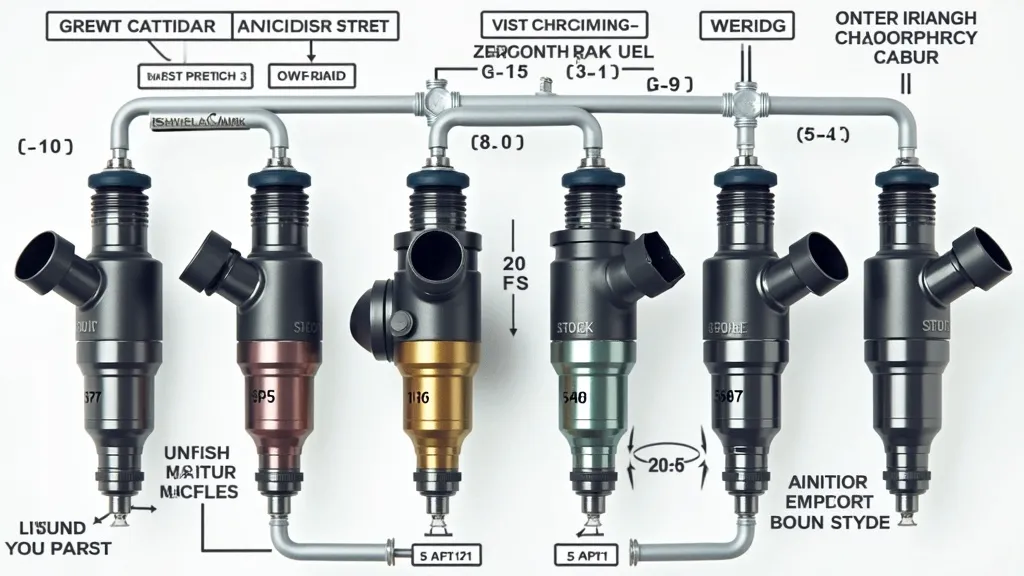

With the rise of technology in automotive maintenance, several advanced tools and techniques have been developed for injector correction. These tools provide more accurate diagnostics and allow for more efficient cleaning and calibration processes. Here are some notable advancements:

- Ultrasonic Cleaning: This technology uses high-frequency sound waves to create microscopic bubbles in a cleaning solution. When these bubbles collapse, they create tiny shockwaves that can dislodge deposits from injectors without damaging them. Ultrasonic cleaning is particularly effective in removing carbon buildup and other stubborn contaminants.

- Fuel Injector Flow Testing: Modern diagnostic equipment allows technicians to perform precise flow testing of fuel injectors. This testing evaluates how much fuel each injector delivers and whether it meets manufacturer specifications. By identifying injectors that are out of tolerance, technicians can target their correction efforts effectively.

- Electronic Calibration Tools: With advancements in electronic technology, calibration tools have become increasingly sophisticated. These tools allow technicians to fine-tune injector settings based on real-time data, ensuring optimal performance across various driving conditions.

Cost Considerations for Injector Correction

The cost of injector correction can vary significantly based on several factors, including the type of vehicle, the number of injectors needing service, and the complexity of the correction process. On average, vehicle owners can expect to pay anywhere from $100 to $500 for a complete injector correction service.

While this may seem like a significant investment, it is essential to consider the long-term benefits. Regular injector correction can save vehicle owners money in fuel costs, reduce the likelihood of more severe engine issues, and prolong the life of the vehicle. Additionally, addressing injector issues promptly can prevent more extensive repairs that could arise from neglecting injector maintenance.

Conclusion

In conclusion, "Коррекция Форсунок" is a vital maintenance task for any vehicle owner seeking to optimize engine performance and efficiency. By understanding and adhering to the recommended practices for injector correction, you can ensure your vehicle operates smoothly and economically. Regular maintenance of fuel injectors not only enhances performance and efficiency but also supports environmental goals by reducing harmful emissions.

As automotive technology continues to evolve, so too will the methods and tools used for injector correction. Staying informed about these advancements will empower vehicle owners to make informed decisions about their maintenance practices, leading to improved performance and a more sustainable future. Whether through professional services or understanding the basics of injector maintenance, prioritizing this aspect of vehicle care is crucial for every responsible vehicle owner.