Understanding Fuel Injector Calibration

Fuel injector calibration, known as "Коррекция Форсунок," is an essential process in automotive maintenance aimed at optimizing engine performance and fuel efficiency. This guide explores the intricacies of injector calibration, its importance in vehicle maintenance, and the benefits it offers in terms of fuel economy and engine longevity.

The Importance of Fuel Injector Calibration

Fuel injector calibration, or "Коррекция Форсунок," is a critical aspect of vehicle maintenance that ensures your engine runs smoothly and efficiently. This process involves adjusting the fuel injectors to deliver the optimal amount of fuel to the engine, thereby enhancing performance and reducing emissions. The significance of fuel injector calibration cannot be overstated, as it directly impacts not just vehicle performance, but also fuel economy and environmental considerations.

How Fuel Injectors Work

Fuel injectors are responsible for delivering fuel into the engine's combustion chamber. They need to operate with precision to ensure the right air-fuel mixture is achieved for combustion. Over time, injectors can become clogged or worn, leading to inefficient fuel delivery and decreased engine performance. The fuel injectors atomize the fuel, allowing it to mix effectively with air for optimal combustion. This requires not only proper calibration but also the right fuel pressure and injector timing to function correctly. When the fuel injectors are not calibrated properly, it can lead to a variety of issues including engine misfires, hard starting, and even catalytic converter damage.

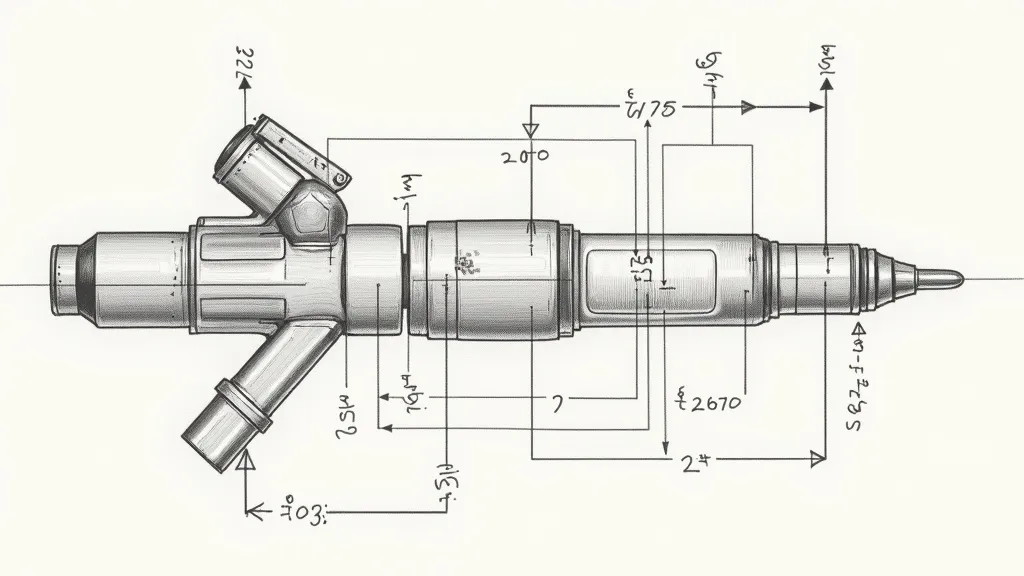

Steps Involved in Injector Calibration

The calibration process typically involves the following steps:

- Diagnosis: Technicians use diagnostic tools to assess the performance of the injectors and identify any issues. This can involve scanning the vehicle's onboard computer for error codes, performing a visual inspection, and conducting tests to evaluate fuel delivery rates.

- Cleaning: Clogged injectors are cleaned to remove deposits that can hinder fuel flow. This cleaning can be done using ultrasonic cleaning methods or chemical injector cleaners that dissolve carbon build-up in the injectors.

- Adjustment: The injectors are adjusted to ensure they deliver the correct amount of fuel. This may involve changing the fuel pressure regulator settings, modifying the injector pulse width, or even replacing faulty injectors if they cannot be calibrated to meet specifications.

- Testing: After calibration, injectors are tested to verify improvements in fuel delivery and engine performance. This testing can include flow testing to measure the volume of fuel delivered by each injector and ensuring that all injectors are operating consistently.

Benefits of Regular Injector Calibration

Regular calibration of fuel injectors offers numerous benefits:

- Improved Fuel Efficiency: Proper calibration ensures optimal fuel delivery, improving fuel economy. When injectors are functioning as intended, your vehicle can achieve better mileage, saving you money at the pump.

- Enhanced Engine Performance: Calibrated injectors contribute to smoother engine operation and better acceleration. This performance enhancement can not only make your driving experience more enjoyable but also increase the vehicle's responsiveness in various driving conditions.

- Reduced Emissions: Efficient fuel combustion reduces harmful emissions, contributing to a cleaner environment. By ensuring that fuel is burned completely, calibrated injectors help minimize the output of pollutants such as hydrocarbons, carbon monoxide, and nitrogen oxides.

- Longevity of Engine Components: Proper fuel delivery reduces wear on engine components, extending the engine's lifespan. By keeping the combustion process efficient, you can prevent damage to critical components like piston rings, valves, and the exhaust system.

Choosing a Professional for Injector Calibration

It is essential to select a qualified technician for fuel injector calibration to ensure accurate adjustments and optimal performance. Look for professionals with experience and access to advanced diagnostic tools. When choosing a service provider, consider factors such as the technician's certifications, the equipment used for calibration, and customer reviews. A reputable shop will often provide a warranty on their work, giving you peace of mind that the calibration has been performed correctly.

Comparison of Calibration Techniques

Understanding the different calibration techniques can help you make an informed choice about how best to maintain your fuel injectors. Here’s a more detailed comparison of the two primary techniques used in fuel injector calibration:

| Technique | Advantages | Disadvantages |

|---|---|---|

| Manual Adjustment | Low cost, simple tools, and techniques can be used. | Less precise, time-consuming, and may require significant expertise to achieve acceptable results. |

| Computerized Calibration | High precision, efficient process, and often includes data logging for performance tracking. | Higher cost, requires specialized equipment, and may not be accessible to all mechanics. |

FAQs

Q: How often should fuel injectors be calibrated?

A: It is recommended to calibrate fuel injectors every 30,000 to 50,000 miles, or as advised by your vehicle manufacturer. However, if you notice any performance issues, it may be beneficial to have them checked sooner.

Q: Can I calibrate my fuel injectors myself?

A: While minor adjustments are possible, it is best to leave calibration to professionals to ensure accuracy and prevent damage. The intricacies involved in calibrating injectors require specific knowledge and tools that most car owners do not possess.

Q: What symptoms indicate the need for injector calibration?

A: Symptoms include rough idling, decreased fuel efficiency, poor acceleration, and engine stalling. If you notice these signs, it's time for a check-up. Ignoring these symptoms can lead to more severe engine problems down the line.

Common Causes of Injector Issues

Understanding what can lead to fuel injector problems is essential for prevention and timely maintenance. Here are some common causes:

- Contaminated Fuel: Fuel that is dirty or contaminated can lead to clogged injectors, reducing their efficiency. This can occur from poor-quality fuel or from sediment in the fuel tank.

- Fuel Filter Issues: A clogged fuel filter can restrict the flow of fuel to the injectors, leading to inadequate fuel delivery. Regularly replacing the fuel filter can help prevent this problem.

- Electrical Problems: Fuel injectors are electronically controlled, and issues with the electrical system, such as shorts or failures in the injector driver circuit, can cause injectors to malfunction.

- Wear and Tear: Over time, fuel injectors can wear out due to the constant exposure to high pressure and heat. This can lead to leaks, reduced spray patterns, and overall inefficiency.

Signs of a Failing Fuel Injector

Recognizing the signs of a failing fuel injector can save you from expensive repairs. Besides the symptoms mentioned previously, consider the following:

- Check Engine Light: If your vehicle's check engine light is illuminated, it could indicate injector issues among other problems. A diagnostic scan can help pinpoint the source.

- Engine Misfires: If the engine is misfiring, it could be due to a malfunctioning injector that is not supplying enough fuel or is leaking fuel uncontrollably.

- Unusual Engine Sounds: A rough-running engine that produces unusual sounds could indicate an injector problem. Listen for knocking or pinging noises which could suggest poor combustion.

- Increased Emissions: If your vehicle is producing more emissions than normal, it could indicate incomplete combustion due to faulty injectors.

Preventive Measures for Injector Health

To maintain healthy fuel injectors and prolong their lifespan, consider the following preventive measures:

- Use Quality Fuel: Always choose high-quality fuel from reputable sources to minimize the chances of contamination and deposits forming in the injectors.

- Regular Maintenance: Include fuel system inspections in your routine vehicle maintenance schedule. This can help identify issues before they escalate.

- Fuel Additives: Occasionally using fuel additives designed to clean injectors can help keep them functioning properly. These additives can dissolve carbon deposits and improve fuel flow.

- Replace Fuel Filters: Replace the fuel filter as recommended by your vehicle manufacturer to prevent any debris from reaching the injectors.

Future of Fuel Injector Technology

The technology behind fuel injectors continues to evolve, with new advancements aimed at improving efficiency and reducing emissions. Some of the exciting developments in this area include:

- Direct Injection Systems: These systems inject fuel directly into the combustion chamber at high pressure, allowing for more precise control of fuel delivery and combustion. This often results in better performance and lower emissions.

- Multi-Point Injection: In this system, each cylinder has its own injector, providing enhanced control over the air-fuel mixture and significantly improving fuel efficiency.

- Smart Injectors: Future fuel injectors may incorporate smart technology that adjusts fuel delivery based on real-time data from the engine, improving performance and efficiency even further.

Conclusion

In conclusion, fuel injector calibration is a vital maintenance task that offers significant benefits in terms of performance, economy, and environmental impact. Regular attention to this aspect of vehicle care can lead to long-term savings and a more enjoyable driving experience. By understanding the importance of fuel injectors, recognizing the symptoms of malfunction, and adhering to a proactive maintenance schedule, vehicle owners can ensure their engines operate at peak performance for years to come. As technology advances, staying informed about new developments in fuel injection systems will also be crucial for optimizing vehicle efficiency and performance.