Understanding Fuel Injector Correction

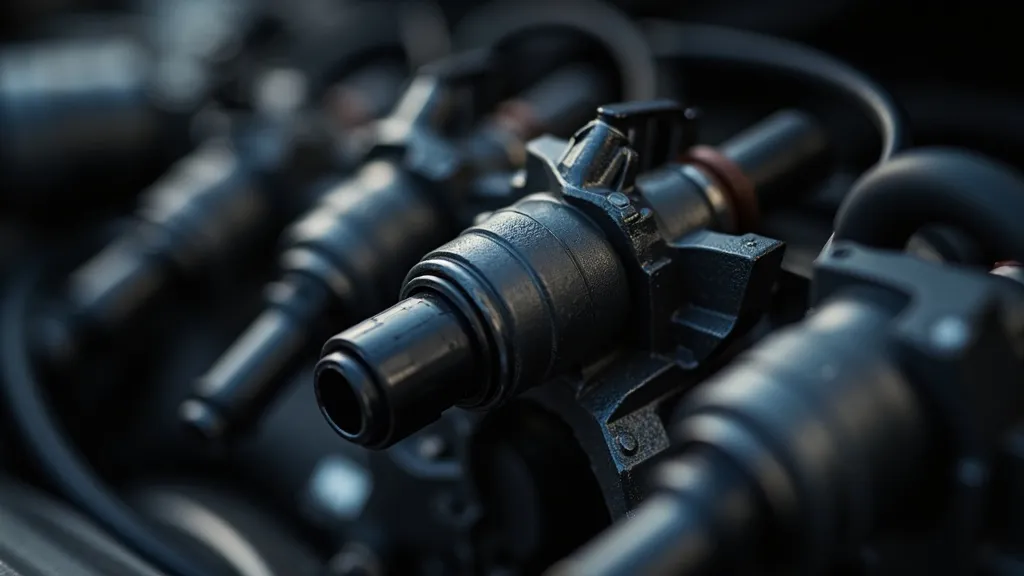

This guide delves into the intricacies of fuel injector correction, a crucial process for maintaining optimal engine performance. Fuel injectors are essential components in modern vehicles, responsible for delivering precise amounts of fuel to the engine's combustion chamber. Proper correction ensures efficiency, reduces emissions, and enhances overall vehicle performance. Through detailed analysis, we explore the significance of this process and its impact on automotive engineering.

Introduction to Fuel Injector Correction

Fuel injectors play a pivotal role in the modern automotive landscape, ensuring that engines receive the precise amount of fuel necessary for optimal combustion. The term "Коррекция Форсунок" refers to the adjustment or correction of these injectors to maintain their efficiency and performance. Proper correction of fuel injectors is crucial as it impacts fuel economy, emission levels, and the overall health of the engine. With the increasing complexity of automotive technologies, understanding fuel injector correction has never been more essential for vehicle maintenance and performance optimization.

The Importance of Fuel Injector Correction

Fuel injector correction is vital for several reasons. Firstly, it ensures that the engine runs smoothly by providing the exact amount of fuel needed for combustion. This precision helps in optimizing fuel consumption, thus reducing the cost of fuel for the vehicle owner. Additionally, well-adjusted injectors contribute to lower emissions, which is increasingly important given global environmental regulations. Furthermore, proper fuel injector correction enhances engine longevity, minimizing wear and tear on engine components that could lead to costly repairs down the line.

How Fuel Injector Correction Works

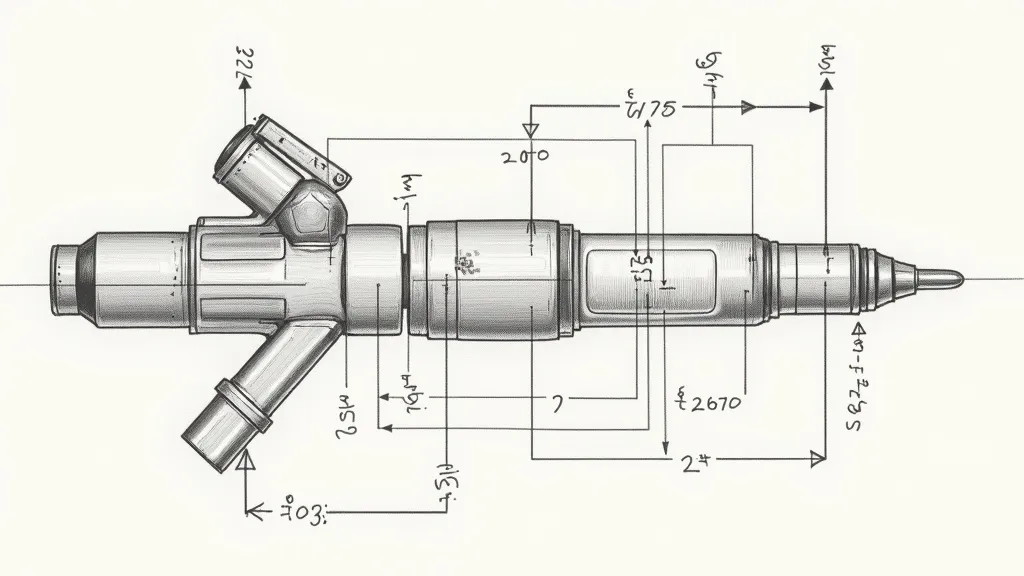

Fuel injector correction involves several steps, starting with diagnosing the injectors to identify any discrepancies in fuel delivery. Technicians use specialized equipment to measure the amount of fuel being injected into the combustion chamber. If the injectors are delivering more or less fuel than required, adjustments are made to bring them back to their optimal state. This process often involves recalibrating the electronic control unit (ECU) that manages the injectors. The ECU utilizes data from various sensors to determine the correct fuel-to-air ratio, and any miscalibrations can lead to significant performance issues. A thorough understanding of the vehicle's fuel management system is essential for effective injector correction.

Benefits of Proper Injector Correction

- Improved Fuel Efficiency: With correct fuel delivery, the engine uses fuel more efficiently, leading to better mileage. This not only saves money for the driver but also reduces the overall environmental impact of fuel consumption.

- Reduced Emissions: Accurate fuel injection contributes to cleaner combustion, resulting in fewer pollutants being released into the atmosphere. This is particularly important in urban areas where air quality is a growing concern.

- Enhanced Engine Performance: Properly corrected injectors ensure that the engine operates at its peak, providing smooth and reliable performance. This can translate to a more enjoyable driving experience with better acceleration and responsiveness.

- Lower Maintenance Costs: Regular correction and maintenance of fuel injectors can prevent more serious engine problems that can arise from improper fuel delivery, ultimately saving vehicle owners money on repairs.

- Prolonged Engine Lifespan: Consistent and accurate fuel delivery minimizes unnecessary strain on engine components, thereby extending the lifespan of the engine and its associated systems.

Challenges in Fuel Injector Correction

While the benefits are clear, achieving precise fuel injector correction can be challenging. It requires skilled technicians and sophisticated diagnostic tools. Moreover, the complexity of modern engines, with their myriad of sensors and electronic components, adds another layer of difficulty to the correction process. Technicians must be adept at interpreting data from various sensors, such as the oxygen sensor, fuel pressure sensor, and mass airflow sensor, to accurately diagnose and correct fuel injector issues. Additionally, variations in fuel quality and environmental conditions can also affect injector performance, making regular assessments all the more necessary.

Industry Practices and Standards

The automotive industry has established various standards for fuel injector correction. These standards ensure consistency and reliability in the correction process. Manufacturers often provide detailed guidelines and protocols to be followed by service centers and technicians. Adhering to these standards is crucial for maintaining warranty conditions and ensuring customer satisfaction. It's important for technicians to stay updated on the latest industry practices, as advancements in technology and methodologies continue to evolve. Regular training and certifications can help technicians remain proficient in the latest fuel injector correction techniques and tools.

Common Questions About Fuel Injector Correction

Q: How often should fuel injectors be corrected?

A: It's typically recommended to check and correct fuel injectors every 30,000 miles, but this can vary based on the vehicle model and driving conditions. For vehicles that frequently operate in harsh conditions or have a history of fuel quality issues, more frequent checks may be necessary.

Q: Can fuel injector correction be done at home?

A: While some DIY enthusiasts might attempt it, professional correction is advised due to the complexity and precision required. Home mechanics may lack access to the specialized diagnostic equipment needed to accurately assess and correct fuel injector performance. Incorrect adjustments can lead to further engine issues.

Q: What are the signs that fuel injectors need correction?

A: Common signs include reduced fuel efficiency, rough idling, and increased emissions. Additionally, other symptoms may include engine misfires, difficulty starting the engine, or a noticeable decrease in power during acceleration. If any of these signs are present, it's advisable to have the injectors inspected and corrected as needed.

Conclusion: The Future of Fuel Injector Technology

As automotive technology evolves, the role of fuel injectors and their correction becomes even more critical. Innovations in fuel injection systems, such as direct injection and variable valve timing, require even more precise correction techniques. The future promises advancements that will make fuel injector correction more efficient and accessible, further enhancing the performance and sustainability of vehicles worldwide. With the rise of hybrid and electric vehicles, the principles of fuel injector correction may also adapt, focusing on optimizing energy use and emissions in different contexts. As the industry moves towards alternative fuels and advanced propulsion systems, the methodologies for injector correction will likely need to evolve, requiring ongoing education and adaptation from technicians and engineers alike.

Understanding Fuel Injector Types

To appreciate the importance of fuel injector correction, it's essential to understand the different types of fuel injectors used in modern vehicles. The two primary types are port fuel injectors and direct fuel injectors. Port fuel injectors spray fuel into the intake manifold, where it mixes with air before entering the combustion chamber. This method allows for more thorough mixing and can lead to better fuel atomization, improving combustion efficiency.

In contrast, direct fuel injectors inject fuel directly into the combustion chamber at high pressure. This approach can enhance power output and fuel efficiency but requires precise control to avoid issues such as knocking or misfire. Each type of injector has its own characteristics and operates under different conditions, making accurate correction techniques essential for optimal performance.

Factors Affecting Fuel Injector Performance

Several factors can affect the performance of fuel injectors, necessitating regular checks and potential corrections. One significant factor is the quality of fuel used. Contaminated or low-quality fuel can lead to clogging or deposits forming on the injectors, which can hinder their performance. Regular use of fuel additives designed to clean the fuel system can help mitigate this issue, but they are not a substitute for proper maintenance.

Another factor is the vehicle's operating conditions. Frequent stop-and-go driving, extreme weather conditions, or towing heavy loads can put added stress on the fuel injection system, making it more susceptible to issues. Additionally, modifications to the engine, such as performance chips or upgrades, can alter the fuel requirements and necessitate recalibration of the injectors.

The Role of Technology in Injector Correction

Advancements in technology have significantly impacted how fuel injector correction is performed. Modern diagnostic tools equipped with advanced software can provide detailed insights into injector performance, allowing technicians to make more informed decisions. These tools can analyze fuel flow rates, pressure, and timing, providing a comprehensive picture of the injectors’ operational status.

Moreover, some systems now integrate real-time data monitoring, enabling continuous assessment of injector performance while the vehicle is in operation. This capability can lead to proactive maintenance strategies, addressing potential issues before they escalate into significant problems. As technology continues to advance, we can expect even more sophisticated solutions for fuel injector correction, ultimately enhancing vehicle performance and efficiency.

Environmental Considerations

With growing concerns about climate change and air quality, the automotive industry is under increasing pressure to reduce emissions. Fuel injector correction plays a crucial role in addressing these environmental challenges. By ensuring that fuel injectors deliver the optimal amount of fuel for combustion, vehicles can achieve lower emissions and improved fuel economy.

As stricter emissions regulations are implemented worldwide, the demand for efficient fuel injection systems will only increase. Automakers are investing in research and development to create more advanced fuel injection technologies that not only meet regulatory standards but also contribute to a more sustainable future. This shift towards greener technologies means that fuel injector correction will become even more critical as vehicles transition towards alternative fuels and electrification.

The Economic Impact of Fuel Injector Correction

Proper fuel injector correction can have significant economic implications for both vehicle owners and the broader automotive industry. For individual drivers, improved fuel efficiency translates directly into lower fuel costs. This is particularly important in an era of fluctuating fuel prices, where every mile per gallon counts. Additionally, reducing the frequency and severity of engine repairs can lead to substantial savings over time.

On a larger scale, when more vehicles on the road operate efficiently due to correct fuel injector performance, the overall demand for fuel decreases. This reduction in fuel consumption can contribute to lower greenhouse gas emissions and less dependency on fossil fuels, aligning with global sustainability goals. Consequently, the automotive industry has a vested interest in promoting fuel injector correction as a means of enhancing vehicle performance while supporting environmental initiatives.

Future Trends in Fuel Injection Technology

Looking forward, several trends are emerging in fuel injection technology that will shape the future of fuel injector correction. As electric vehicles (EVs) become more prevalent, the automotive industry is exploring the integration of advanced fuel management systems that can optimize hybrid powertrains. This development will require a new approach to fuel injector correction, focusing on compatibility with electric and hybrid technologies.

Furthermore, the rise of autonomous vehicles may also influence fuel injector technologies. With the advancement of artificial intelligence and machine learning, future vehicles could be equipped with systems that dynamically adjust fuel delivery based on real-time driving conditions and performance data, potentially eliminating the need for manual correction altogether. This level of automation could revolutionize how fuel injectors are managed, leading to improvements in both efficiency and convenience for drivers.

Conclusion: The Ongoing Need for Expertise

As we navigate the complexities of modern automotive technology, the need for expertise in fuel injector correction remains paramount. Technicians must be well-versed in the latest tools, techniques, and technologies to ensure that fuel injectors operate at their best. Continuous education and training will be essential in keeping up with the rapid advancements in the field.

In conclusion, fuel injector correction is not merely a maintenance task; it is a critical component of vehicle performance and environmental responsibility. By ensuring that fuel injectors are accurately calibrated and functioning effectively, we can enhance fuel efficiency, reduce emissions, and prolong the lifespan of our vehicles. As technology continues to evolve, the methods and practices surrounding fuel injector correction will also adapt, paving the way for a more sustainable and efficient automotive future.