Understanding Injector Calibration Processes

This article explores the critical process of injector calibration, known as "Коррекция Форсунок" in Russian. Essential for maintaining engine efficiency, injector calibration ensures the precise delivery of fuel to the engine. This process helps in optimizing performance, reducing emissions, and prolonging engine life, making it vital for automotive professionals and enthusiasts alike.

Introduction to Injector Calibration

In the world of automotive engineering, the term "Коррекция Форсунок," or injector calibration, is pivotal for ensuring that engines run smoothly and efficiently. This process involves adjusting the fuel injectors so that they deliver the correct amount of fuel to the engine cylinders. Proper calibration is essential for achieving optimal engine performance, reducing emissions, and extending the lifespan of the engine components. When fuel injectors are not calibrated correctly, it can lead to an array of issues including poor engine performance, increased fuel consumption, and higher emissions, which can ultimately result in costly repairs and a negative impact on the environment.

The Importance of Injector Calibration

As vehicle technology advances, the precision required in fuel delivery systems becomes increasingly critical. Injector calibration is not just a technical necessity but a key factor in the overall health of an engine. Calibrated injectors ensure that fuel is atomized properly, allowing for complete combustion and maximum energy extraction. This leads to improved fuel efficiency, reduced pollutant emissions, and smoother engine operation. Furthermore, as the automotive industry moves towards more stringent emissions regulations, the importance of injector calibration has never been more pronounced. A well-calibrated fuel injection system can help manufacturers meet these regulations while providing consumers with more efficient and cleaner vehicles.

Process of Injector Calibration

The calibration process involves several steps to ensure that injectors are operating correctly:

- Diagnostic Testing: Technicians use specialized diagnostic tools to assess the current performance of the fuel injectors. This initial testing helps identify any issues such as leaks, clogs, or improper spray patterns that may necessitate further action.

- Cleaning: Injectors are cleaned to remove any build-up that could affect fuel flow. This cleaning process often involves ultrasonic cleaning or chemical cleaning solutions that effectively dissolve deposits without damaging the injectors.

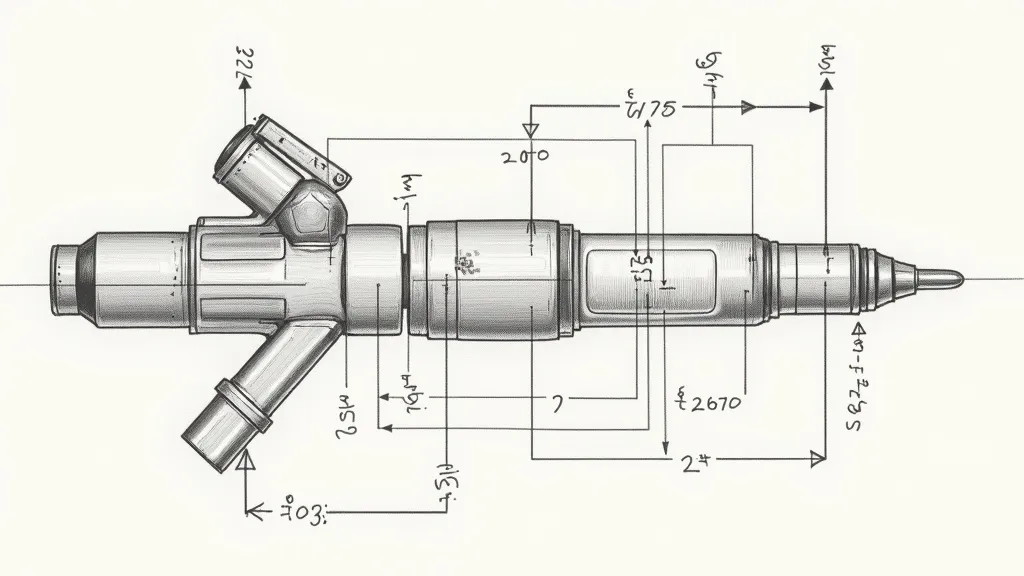

- Adjustment: Using precision instruments, adjustments are made to align the injectors' spray pattern and flow rate with the manufacturer's specifications. Technicians may use flow benches to measure the output and adjust the injectors accordingly to achieve the desired performance metrics.

- Testing and Verification: After adjustments, a series of tests ensure the injectors are calibrated correctly. This may involve running the engine under various conditions to confirm that fuel delivery is consistent and efficient across different operating scenarios.

Benefits of Injector Calibration

- Enhanced Performance: Properly calibrated injectors improve engine responsiveness and power output. This can lead to a more enjoyable driving experience as the vehicle accelerates more smoothly and effectively.

- Fuel Efficiency: Accurate fuel delivery minimizes waste and maximizes fuel economy. By ensuring that the right amount of fuel is delivered at the right time, drivers can experience significant savings at the pump.

- Lower Emissions: Optimization reduces the emission of harmful gases, aligning with environmental standards. This is especially important in urban areas where air quality is a significant concern.

- Extended Engine Life: Calibration reduces wear and tear on engine components, contributing to longer engine life. Proper injector function prevents issues such as knocking and misfiring, which can lead to premature engine failure.

Comparison Table: Injector Calibration Tools

| Tool | Function | Price Range |

|---|---|---|

| OBD-II Scanner | Diagnostic tool for initial assessment of injectors. It interfaces with the vehicle's onboard diagnostics to retrieve data and error codes. | $100 - $500 |

| Ultrasonic Cleaner | Cleans injectors by removing deposits. This device uses high-frequency sound waves to create microscopic bubbles that gently scrub the injectors. | $200 - $1,000 |

| Flow Bench | Tests and adjusts fuel flow rates. It allows technicians to measure the flow characteristics of injectors under various pressures. | $2,000 - $10,000 |

Common Issues Related to Injector Calibration

While the calibration process is essential for optimal engine performance, several common issues can arise if injectors are not calibrated properly:

- Engine Misfires: This occurs when one or more cylinders do not receive the appropriate amount of fuel, leading to incomplete combustion. Misfires can cause rough idling, loss of power, and increased emissions.

- Increased Fuel Consumption: If injectors are leaking or delivering too much fuel, it can result in excessive fuel consumption. Drivers may notice that they are filling up their tanks more frequently, leading to higher operating costs.

- Rough Idle and Stalling: Incorrect fuel delivery can lead to erratic engine behavior, including rough idling and stalling. This can be particularly problematic in stop-and-go traffic.

- Excessive Smoke Emissions: Over-fueling can result in black smoke from the exhaust, indicating that the engine is not burning fuel efficiently. This not only contributes to environmental pollution but can also result in failing emissions tests.

FAQs

Q: How often should injector calibration be performed?

A: It is recommended to calibrate injectors every 30,000 to 50,000 miles, depending on the vehicle's usage and manufacturer guidelines. However, vehicles that frequently operate under extreme conditions may require more frequent calibrations.

Q: Can injector calibration improve fuel economy?

A: Yes, by ensuring precise fuel delivery, injector calibration can significantly improve fuel economy. Proper calibration ensures that the engine runs as efficiently as possible, allowing for better utilization of fuel.

Q: Is injector calibration a DIY task?

A: While cleaning can be a DIY task, calibration typically requires professional equipment and expertise. Attempting to calibrate injectors without the necessary tools and knowledge can lead to further issues and potentially damage the engine.

Understanding Fuel Injection Systems

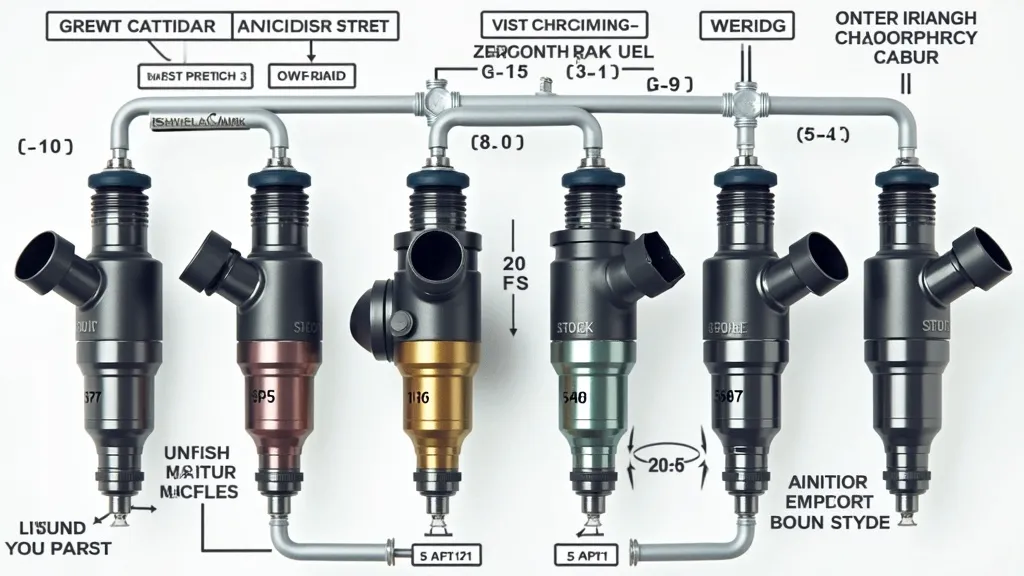

To fully grasp the importance of injector calibration, it is essential to understand how fuel injection systems work. Modern vehicles primarily use either port fuel injection (PFI) or direct fuel injection (DFI) systems. Each of these systems has its own unique characteristics and requires specific calibration approaches.

Port Fuel Injection (PFI)

In a port fuel injection system, fuel is injected into the intake manifold, just before the intake valves. This allows for thorough mixing with air before entering the combustion chamber. The main benefit of PFI is that it promotes better atomization, leading to more complete combustion and reduced emissions. However, PFI systems can be susceptible to carbon build-up on intake valves, which can affect performance over time.

Direct Fuel Injection (DFI)

In contrast, direct fuel injection systems inject fuel directly into the combustion chamber at high pressure. This allows for greater control over fuel delivery and can improve efficiency and power output. However, DFI systems can face challenges related to carbon deposits, as the fuel does not wash over the intake valves like in PFI systems, leading to potential valve sticking and reduced performance.

Advanced Calibration Techniques

With advancements in automotive technology, calibration techniques have evolved significantly. Some of the more advanced calibration methods include:

- Dynamic Calibration: This method involves calibrating injectors while the engine is running, allowing technicians to observe real-time performance and make adjustments on the fly.

- Closed Loop Calibration: In this approach, the engine control unit (ECU) continuously monitors injector performance and makes adjustments based on feedback from various sensors. This ensures that fuel delivery is always optimized for current driving conditions.

- Software Calibration: Many modern vehicles use sophisticated engine management software that allows for precise calibration adjustments. Technicians can use this software to fine-tune injector settings based on performance data and desired outcomes.

Future Trends in Injector Calibration

As the automotive industry continues to evolve, so too do the technologies and techniques used for injector calibration. Some trends that are shaping the future of this field include:

- Increased Automation: As technology advances, more calibration processes are becoming automated, reducing the potential for human error and improving accuracy.

- Integration with Hybrid and Electric Vehicles: With the rise of hybrid and electric vehicles, the calibration processes for fuel injectors will need to adapt to new powertrains and fuel delivery systems.

- Data-Driven Calibration: The use of big data and analytics is becoming more prevalent in calibration processes. By analyzing large sets of performance data, technicians can make more informed decisions regarding calibration adjustments.

Conclusion

Injector calibration, or "Коррекция Форсунок," is a crucial aspect of maintaining vehicle performance and efficiency. By ensuring optimal fuel delivery, it plays a significant role in enhancing engine performance, reducing emissions, and prolonging engine life. Whether you are a professional mechanic or an automotive enthusiast, understanding the importance and process of injector calibration can greatly benefit your approach to vehicle maintenance. As automotive technologies continue to advance, staying informed about the latest calibration techniques and trends will be essential for anyone involved in the field of automotive engineering.

Additional Resources

For those interested in learning more about injector calibration and fuel injection systems, consider exploring the following resources:

- Automotive Engineering Textbooks: Many comprehensive textbooks cover the principles of fuel injection systems and calibration techniques in great detail.

- Online Courses: Various platforms offer online courses focused on automotive technology, including specialized courses on fuel injection and calibration.

- Industry Forums: Participating in automotive forums can provide valuable insights from experienced professionals and enthusiasts alike.

- Manufacturer Workshops: Many OEMs offer workshops and training sessions for technicians focused on the latest calibration tools and techniques.