Understanding Fuel Injector Correction

Fuel injector correction is an essential process in automotive engineering, ensuring optimal engine performance and efficiency. This procedure involves adjusting the injectors to deliver the correct amount of fuel, preventing engine misfires and reducing emissions. Proper calibration can enhance vehicle longevity and operational efficiency, contributing to both environmental sustainability and economic savings.

Introduction to Fuel Injector Correction

Fuel injector correction, known as "Коррекция Форсунок" in Russian, is a critical aspect of maintaining modern engine performance. This process involves fine-tuning the injectors to ensure the precise amount of fuel is delivered to the engine, optimizing combustion and enhancing both performance and fuel efficiency. In this article, we will explore the intricacies of fuel injector correction, its importance, and the steps involved in ensuring your vehicle runs smoothly. Understanding fuel injector correction not only helps in maintaining the efficiency of your vehicle but also plays a significant role in managing emissions and reducing the overall environmental impact of automotive transport.

The Importance of Accurate Fuel Delivery

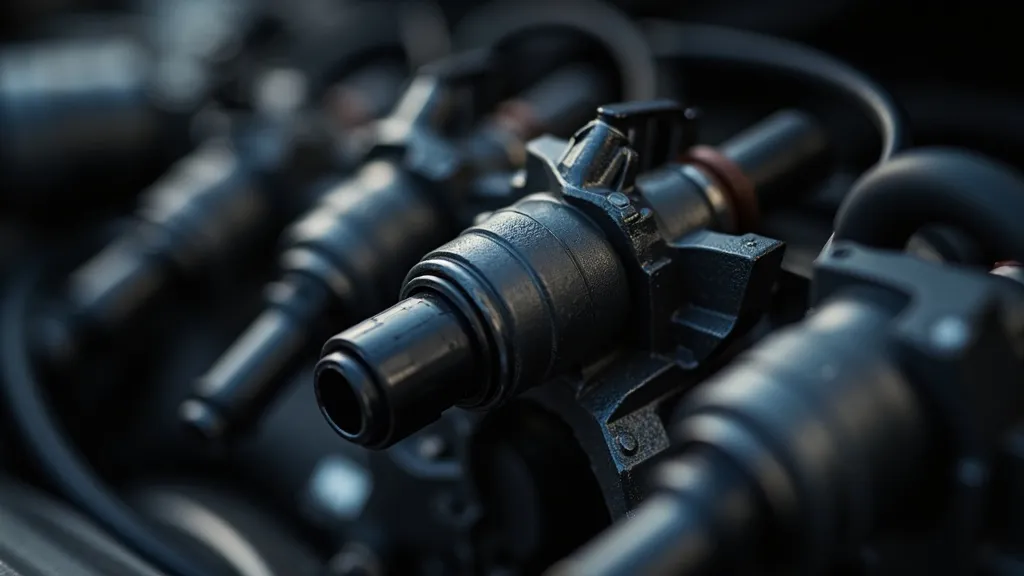

Fuel injectors play a vital role in an engine's overall performance. They are responsible for delivering the exact quantity of fuel required by the engine's control unit based on various parameters such as engine speed, load, and temperature. Inaccurate fuel delivery can lead to several issues, including reduced fuel efficiency, increased emissions, and potential engine damage. Therefore, regular inspection and correction of fuel injectors are crucial for maintaining optimal engine health. Over time, injectors can become clogged with deposits, which can prevent them from delivering fuel properly. This can result in poor engine performance, including rough idling, stalling, and decreased acceleration. Understanding the importance of accurate fuel delivery is essential for vehicle owners who want to maximize both performance and longevity.

Process of Fuel Injector Correction

The process of correcting fuel injectors involves several steps, each critical to ensuring the injectors function correctly. The procedure typically begins with a comprehensive diagnostic test to assess the current state of the injectors. This is often done using specialized diagnostic equipment that can measure the flow rate and spray pattern of each injector. After the initial assessment, the next step is cleaning the injectors to remove any deposits that might hinder their performance. This cleaning process can be done using various methods, including ultrasonic cleaning, which is highly effective in removing stubborn deposits without damaging the injectors.

Once cleaned, the injectors are tested again to evaluate their performance. At this stage, technicians can identify any inconsistencies in fuel delivery and make necessary adjustments. The injectors are then recalibrated using specialized equipment to ensure they deliver fuel accurately according to the engine's requirements. This may involve adjusting the fuel pressure and the duration of the injector pulse. The final step is a thorough road test to ensure that the engine operates smoothly and efficiently with the corrected injectors. Regular maintenance of this process can help prevent future issues and maintain optimal engine performance.

Benefits of Fuel Injector Correction

Regular fuel injector correction offers numerous benefits. Firstly, it ensures efficient fuel combustion, which can significantly enhance engine performance and increase fuel economy. A well-tuned fuel injection system can improve throttle response, allowing the vehicle to accelerate more smoothly and quickly. Secondly, it reduces harmful emissions by ensuring complete combustion of fuel, contributing to environmental sustainability. This is particularly important given the increasing regulations on vehicle emissions in many countries.

Additionally, proper fuel injector correction helps maintain the overall health of the engine. By preventing potential engine damage caused by improper fuel delivery, vehicle owners can avoid costly repairs down the line. Furthermore, regular correction can help prolong the lifespan of not only the injectors but also other engine components that depend on optimal fuel delivery. In summary, the benefits of fuel injector correction extend beyond just performance; they also include financial savings through improved fuel efficiency and reduced maintenance costs.

Technical Insights into Fuel Injector Performance

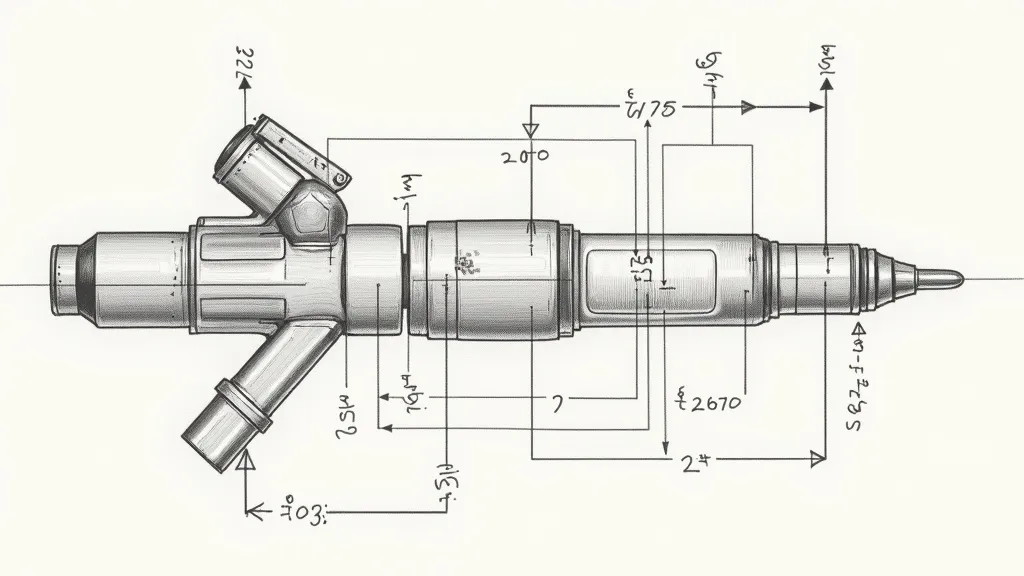

Fuel injectors must operate with high precision to meet the demands of modern engines. They are designed to withstand extreme conditions and must deliver fuel in a finely atomized spray to ensure complete combustion. The correction process involves adjusting the injector's spray pattern and pressure to meet the engine's specific requirements. Advanced diagnostic tools are used to monitor and adjust these parameters, ensuring the injectors perform optimally. For instance, the use of high-speed cameras can visualize the spray pattern of the injectors, allowing technicians to make precise adjustments to enhance fuel atomization.

Moreover, understanding the various types of fuel injectors—such as port fuel injectors, direct injectors, and sequential fuel injectors—can also shed light on the intricacies of correction processes. Each type has its own set of characteristics and operational parameters that must be considered during the correction process. Port fuel injectors, for example, spray fuel into the intake manifold, while direct injectors inject fuel directly into the combustion chamber. This fundamental difference necessitates specific calibration techniques tailored to each type of injector. Thus, expertise in the function and specification of different injector types is crucial for effective correction and maintenance.

Frequently Asked Questions

- What causes fuel injectors to malfunction?

Fuel injectors can malfunction due to clogs from fuel deposits, electrical issues, or wear and tear over time. Regular maintenance can help prevent these issues. Factors such as low-quality fuel, contaminants, and lack of regular maintenance can exacerbate these problems. Additionally, overheating can lead to injector failure, making it essential to monitor engine temperatures and ensure proper cooling.

- How often should fuel injectors be corrected?

It is recommended to have fuel injectors inspected and corrected every 30,000 to 50,000 miles, or as advised by the vehicle manufacturer. However, driving habits, fuel quality, and engine conditions can all influence this timeline. For instance, vehicles driven in harsh conditions or those that frequently carry heavy loads may require more frequent inspections to ensure injectors are functioning correctly.

- Can I perform fuel injector correction myself?

While basic cleaning might be possible at home, precise correction and calibration should be performed by professional technicians using specialized equipment. DIY methods may not achieve the required accuracy and could potentially lead to further issues if not performed correctly.

Comparative Analysis of Fuel Injector Correction Techniques

| Technique | Description | Advantages |

|---|---|---|

| Ultrasonic Cleaning | Uses ultrasonic waves to remove deposits from injectors. | Highly effective in removing stubborn deposits without damaging the injectors. |

| Fuel Additives | Chemical agents added to fuel to clean injectors. | Easy to use and maintain injectors between professional cleanings; can prevent buildup. |

| Professional Calibration | Utilizes advanced diagnostic tools for precision tuning. | Ensures accurate fuel delivery and optimal engine performance; tailored adjustments enhance efficiency. |

| Flow Testing | Measures the fuel flow rate and spray pattern of injectors. | Identifies performance issues early and allows for targeted corrections. |

| Injector Replacement | Involves replacing faulty injectors with new ones. | Guarantees optimal performance when injectors are beyond repair; ensures reliability. |

Challenges in Fuel Injector Correction

Despite the advancements in technology and techniques for fuel injector correction, several challenges persist. One of the primary challenges is the increasing complexity of modern fuel injection systems. As vehicles incorporate more advanced technologies, such as variable valve timing and turbocharging, the requirements for fuel injectors become more stringent. This means that correction techniques must evolve to keep pace with these developments.

Another challenge is the variance in fuel quality. Inconsistent fuel quality can lead to injector performance issues that are difficult to diagnose and rectify. Fuel with high levels of contaminants or lower octane ratings can result in injector fouling and reduced efficiency. As such, maintaining high standards for fuel quality is essential for effective injector performance. Furthermore, the rapid advancement of automotive technology means that technicians must continually update their skills and knowledge to stay abreast of the latest developments in fuel injector technology and correction methods.

The Role of Technology in Fuel Injector Correction

Technology plays a pivotal role in enhancing the accuracy and efficiency of fuel injector correction. The use of advanced diagnostic tools allows technicians to perform more precise measurements of injector performance, enabling them to make informed corrections. For instance, software programs that analyze injector performance data can provide insights into potential issues and recommend specific adjustments. Additionally, computerized fuel management systems can optimize injector timing and fuel delivery, further enhancing engine performance.

Moreover, innovations such as 3D printing are beginning to make their mark in the automotive industry, including the manufacturing of fuel injectors. This technology allows for the creation of highly complex injector designs that can improve performance and reduce emissions. As these advancements continue to develop, they will likely contribute to the ongoing evolution of fuel injector technology and correction techniques, leading to even more efficient and environmentally friendly engines.

Conclusion: The Future of Fuel Injector Technology

As automotive technology continues to evolve, the role of fuel injectors in engine performance becomes increasingly significant. Future advancements may include more sophisticated injector designs and materials, as well as automation in the correction process, enhancing both performance and efficiency. Staying informed and maintaining regular correction procedures will ensure that your vehicle remains in optimal condition, providing both economic and environmental benefits. The integration of data analytics and machine learning into fuel injector systems could also pave the way for predictive maintenance, allowing vehicle owners to address potential issues before they become significant problems.

In conclusion, understanding the intricacies of fuel injector correction is essential for anyone looking to maintain their vehicle's performance and efficiency. The benefits of regular correction extend beyond personal vehicle performance and contribute to broader environmental goals. As technology continues to advance, the methods and techniques for fuel injector correction will undoubtedly evolve, leading to even greater improvements in engine efficiency and sustainability in the future.