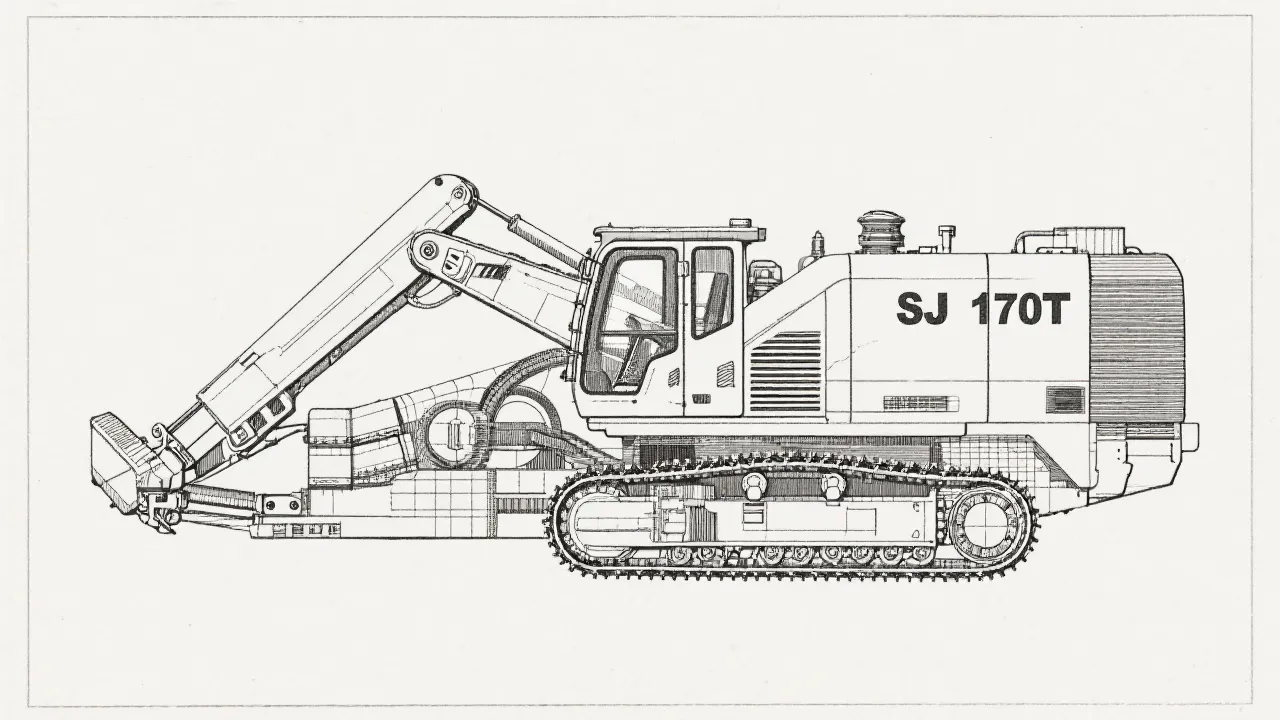

Understanding the Sj 170t Machinery

The Sj 170t machinery is an innovative piece of industrial equipment designed to enhance efficiency in various sectors. Known for its durability and advanced technology, this machine plays a critical role in production lines, offering optimized performance and reliability. This article delves into the specifics of the Sj 170t, exploring its features, applications, and the impact on modern industrial processes.

Introducing the Sj 170t Machinery

The Sj 170t is a robust, multi-functional piece of equipment predominantly used in industrial manufacturing processes. Designed with advanced technology, it supports a range of applications that demand precision and efficiency. Its construction is aimed at catering to high-volume production while maintaining minimal downtime, a feature that highlights its significant role in boosting operational productivity. In a world where manufacturing speed and adaptability to market changes are crucial, the Sj 170t stands out as a reliable partner for businesses aiming to modernize their practices.

Key Features of Sj 170t

The Sj 170t machine is equipped with state-of-the-art features that set it apart from its predecessors and competitors in the market. Its durability stems from the high-quality materials used in its construction, ensuring longevity even under intense operational stress. Furthermore, the machine integrates cutting-edge automated technology, allowing for seamless interactions with digital control systems. This integration enables real-time data collection and analysis, which is critical for optimizing production processes.

Furthermore, the Sj 170t boasts an intuitive user interface that simplifies operation, reducing the need for extensive training and thus shortening the deployment time within production facilities. Perhaps one of the most notable aspects of this machinery is its energy efficiency, contributing to cost reductions in power consumption over time without compromising performance. This aspect is increasingly important in a global climate that favors sustainability, making the Sj 170t not just a tool for efficiency but a step toward responsible manufacturing practices.

Applications and Benefits

The versatility of the Sj 170t makes it suitable for a wide array of applications within the industrial sector. It can be adapted for use in automotive manufacturing, packaging, and even in sectors such as agriculture, where precision and reliability are paramount. In automotive manufacturing, for example, the Sj 170t can handle intricate processes such as assembling components with high accuracy, while in packaging, it can efficiently fill, label, and seal products. The machine delivers consistent performance, which is crucial for maintaining product standards and quality control.

The benefits of integrating the Sj 170t into a production line include improved cycle times, enhanced precision in product finishing, and a significant reduction in labor costs due to automation. For instance, the automation features could result in a notable decrease in manual handling tasks, allowing workers to focus on higher-value tasks that require human oversight and decision-making. Furthermore, its robust nature reduces the frequency of maintenance and potential operational disruptions, fostering a smoother workflow and consequently increasing overall manufacturing outputs.

The Impact on Modern Industrial Processes

The introduction of the Sj 170t machinery has had a transformative effect on modern industrial processes. By streamlining operations, it facilitates the faster delivery of goods to market, a key advantage in today’s highly competitive business environment. The ability of companies to quickly respond to market demands is enhanced, providing them with a substantial edge over competitors. Companies leveraging this machinery can optimize their supply chains, reduce lead times, and ultimately deliver products to customers more swiftly and efficiently, thereby enhancing customer satisfaction and loyalty.

Expert Insights

Industry experts have praised the Sj 170t for its forward-thinking design and operational efficiency. Many industry professionals view it as an essential component for companies looking to future-proof their operations. As companies aim to adopt more sustainable practices, the energy efficiency of the Sj 170t becomes a noteworthy attribute. By reducing energy consumption without sacrificing quality, businesses can lower their carbon footprint, aligning with global sustainability goals. This shift towards sustainability is not merely beneficial for the environment; it is increasingly demanded by consumers who prefer to engage with brands that prioritize eco-friendly practices.

Furthermore, experts highlight the importance of keeping up with technological advancements in manufacturing. The integration of IoT and AI capabilities allows the Sj 170t to become a part of the Industry 4.0 movement, where machines not only perform tasks but also learn and adapt based on operational data. This trend indicates that the Sj 170t is not just an improvement over older models, but a significant leap toward innovative manufacturing practices that will define the future of industries worldwide.

Comparative Analysis Table

| Feature | Sj 170t | Older Models |

|---|---|---|

| Durability | High | Moderate |

| Technology | Advanced Automation | Basic Automation |

| Energy Efficiency | Exemplary | Standard |

| User Interface | Intuitive | Complex |

| Data Integration | Real-time Analytics | Manual Reporting |

Frequently Asked Questions (FAQs)

- What industries benefit the most from the Sj 170t? This machine is highly beneficial in automotive, packaging, and agricultural sectors due to its precision and efficiency. Industries that rely on both high-quality output and scalability are among those that can gain substantial advantages from implementing the Sj 170t into their processes.

- How does the Sj 170t contribute to energy conservation? It incorporates advanced technology that optimizes power usage, thereby reducing overall consumption. Algorithms that monitor and adjust energy use ensure that the machine operates within necessary power parameters without wasting energy, making it a cost-effective solution for businesses.

- Is the Sj 170t easy to integrate into existing production lines? Yes, its design allows for easy implementation without extensive modification to current systems. Adaptations are typically straightforward, enabling businesses to experience minimal disruption during the integration process.

- What is the typical maintenance schedule for the Sj 170t? Regular maintenance is minimal due to its sturdy construction and reliable performance. Scheduled checks are recommended but are often less frequent than those required for older or less reliable machines.

- Can the Sj 170t adapt to specific production needs? Absolutely, the Sj 170t is designed with flexibility in mind. Depending on the specific requirements of the production process, modifications can be made to optimize it for particular tasks, making it a versatile choice for manufacturers.

Technical Specifications

Understanding the technical specifications of the Sj 170t is crucial for businesses considering this equipment. Below is a breakdown of its main specifications:

- Power Supply: 400V, 50Hz, three-phase

- Weight: Approximately 3,500 kg

- Max Load Capacity: 1000 kg

- Dimensions: 3000mm x 1500mm x 1900mm (LxWxH)

- Speed: Up to 120 cycles per minute depending on application

- Control System: PLC with touch screen interface

These specifications underline the capacity and performance potential of the Sj 170t, showcasing its suitability for high-demand industrial applications.

Case Studies and Real-World Applications

To illustrate the effectiveness of the Sj 170t in real-world scenarios, several case studies can be examined. These cases demonstrate how various companies across different sectors have successfully integrated the Sj 170t into their operations.

Case Study 1: Automotive Manufacturing

A leading automotive manufacturer integrated the Sj 170t for its assembly line. Prior to this, the company faced challenges with cycle times and product defects. After deploying the Sj 170t, the company reported a 30% reduction in cycle times and a 25% decrease in defects thanks to the precision and speed of the machinery. The automation reduced the labor dependency by 40%, allowing their human resources to focus on more intricate aspects of production and quality assurance.

Case Study 2: Food Packaging Industry

In the food packaging sector, a company struggled with inconsistencies in packaging size and sealing. After introducing the Sj 170t, not only were they able to standardize their processes but they also observed a significant boost in throughput. The machine's ability to adapt to different package sizes without extensive reconfiguration saved the company both time and money. The energy efficiency of the Sj 170t further enhanced their sustainability profile, appealing to a growing base of eco-conscious consumers.

Case Study 3: Agricultural Manufacturing

A manufacturer of agricultural equipment decided to implement the Sj 170t after facing challenges related to production delays and labor shortages. The Sj 170t allowed them to automate complex tasks that previously required large teams. Post-implementation, they recorded a 50% increase in production efficiency and much-improved workplace safety due to reduced manual handling. This case exemplifies how the Sj 170t can meet the demands of industries that require both speed and precision.

Future Trends in Industrial Machinery

The landscape of industrial machinery is continually evolving, driven by advancements in technology and changes in market demand. As industries move towards greater automation and smart manufacturing practices, machinery like the Sj 170t is at the forefront of these trends. Future machinery is expected to incorporate even more sophisticated AI capabilities which will enhance their adaptability and responsiveness to production environments.

Moreover, there is a growing emphasis on modular designs that allow machines to be scaled up or down depending on the requirements of the production process. This flexibility can significantly reduce costs and increase efficiency, aligning with the evolving demands of manufacturers. As sustainability becomes a key focus for industries worldwide, innovations aimed at enhancing energy efficiency and reducing waste will likely shape the future of machinery design and functionality.

Conclusion

The Sj 170t embodies a pivotal advancement in industrial machinery, offering transformative benefits that align with modern production needs and ecological considerations. As companies continue to navigate the demands of the 21st century, incorporating such technologies will be crucial for staying competitive and sustainable in the global market. The adaptability, efficiency, and reliability of the Sj 170t make it not just a machine, but a strategic asset in the journey towards a smarter manufacturing future.